Why is there so much oil under the Gulf of Mexico?

The Mississippi and the other great rivers that carry sediment from the Rocky Mountains have been dumping rich organic mud into the Gulf for millions of years. The Gulf, which is really a big hole, was made 60 to 80 million years ago by plate tectonics and the initial rifting of the Yucatán and Cuba off North America as the continents responded to the big collision that made the Rocky Mountains.

It sounds as though the Gulf is a 580,000-square-mile compost heap.

But without the abundance of oxygen in the sea bottom. The Gulf is a place where water circulates with difficulty, and that prevents the oxidation of organic material as it spills into this ocean basin. If the material oxidizes, it loses its organic energy — oxygen combines with hydrogen and carbon — and the game is over. No oil or gas.

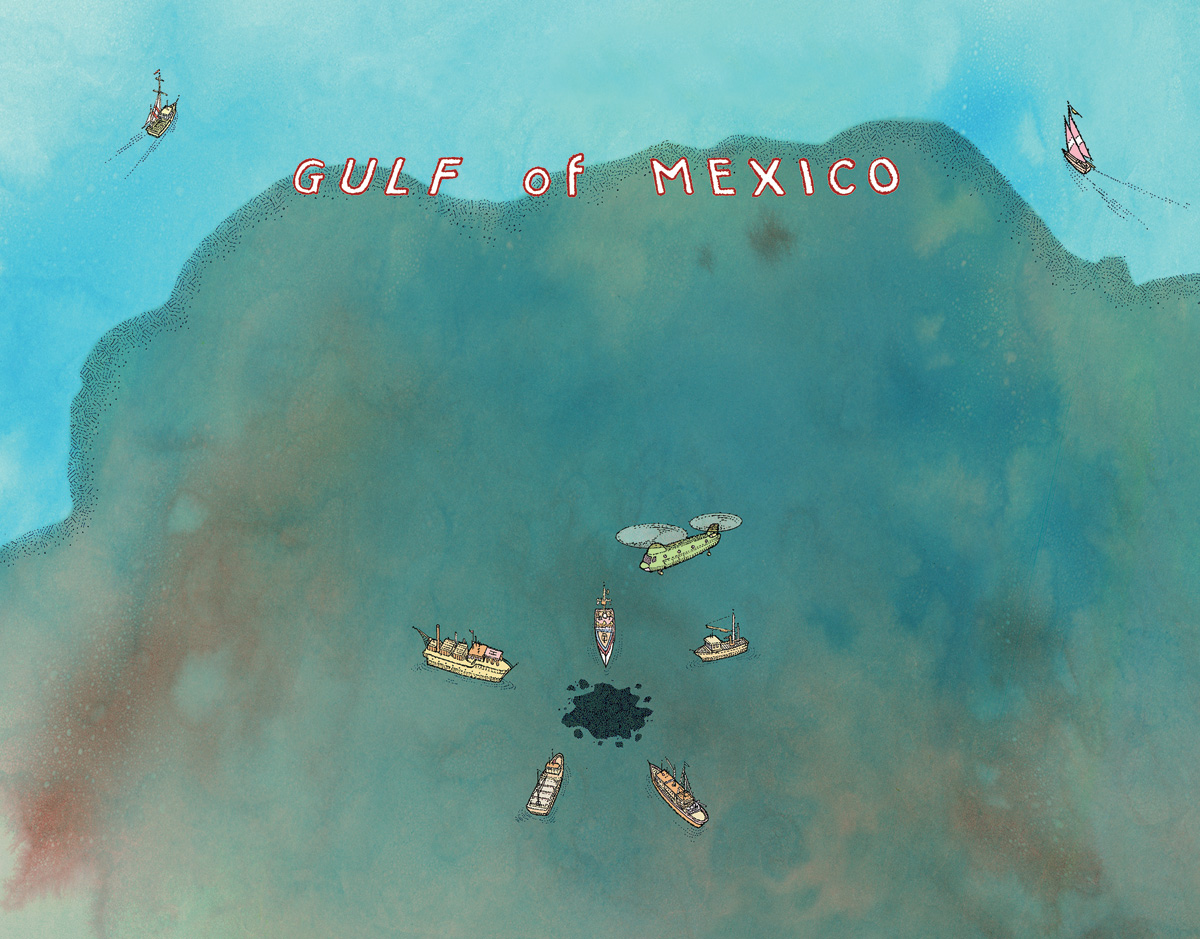

Summarize what happened on BP’s Deepwater Horizon this past spring.

BP started drilling the Macondo well on February 15 about 40 miles off the southeastern coast of Louisiana. This was an exploratory well; the rig was in 5000 feet of water and was drilling through a further 18,000 feet of seabed. By March the rig was in serious trouble. It was taking what are called kicks — blobs of natural gas forcing their way up the drill pipe and burping onto the rig floor. Those kicks were coming every few days. It’s the energy from the buoyant mass of oil and gas trying to vent to the surface. (Although kicks are unwanted on the surface, they can be a good sign in the oil business, because the bigger these pressure pulses, the larger the oil and gas reservoir.)

How should crews have reacted to the kicks?

Primarily by keeping the pipe filled with heavy drilling mud, which is a special mixture of heavy clays that is much denser than seawater. A gallon of water weighs about 8.9 pounds. A gallon of this drilling mud weighs up to 22 pounds.

The high density of the mud keeps the natural gas and oil down in the reservoir?

Right, but the mud is expensive, and it appears that BP was trying to save money. They were also rushing to finish the well, which had been fighting them the whole time, making them weeks behind schedule. The people on the rig called it the “Well from Hell.” On the morning of April 20, the crew from Transocean (the owner of the rig), over the strong objections of their own drilling superintendent, was ordered by BP to take the heavy drilling mud out of the drill pipe and replace it with seawater. That was the triggering event that allowed the gas and oil to blow out onto the Deepwater Horizon rig floor — then a random spark ignited a tremendous explosion. The rig sank, allowing the free release of the pressure and the energy of all that oil and gas into the ocean. The rest is history.

We are all now familiar with the term blowout preventer or BOP. What is it, and what went wrong?

The blowout preventer is a powerful hydraulic device that clamps the riser pipe shut in case of just such an uncontrolled kick. It is the thing that saves you when everything else has failed — thus the name. The blowout preventer had been giving Transocean trouble for a month before the explosion because of hydraulic leaks and electronics problems. The key to any hydraulic system is that if it leaks, it doesn’t have the power of compression that it needs to function properly. Now that the Deepwater Horizon’s BOP has been returned to the surface for autopsy, we will learn just what was leaking, and where.

Another problem was that the blowout preventer was apparently too small. As BP and the deepwater oil industry in general migrated to deeper and deeper water to find new oil and gas, they had to use stronger and stronger drill pipe and casing, and the BOP was no longer sufficiently strong to slam shut in this emergency.

Was this a matter of loose oversight? If the Deepwater Horizon had been under another country’s jurisdiction, might this disaster have been prevented?

Those kicks would have been a giant red flag anywhere else in the world.If this well had been drilled in the North Sea, for example, the British government would have shut it down a month before the blowout. And they would have had hearings on what to do about it. The government probably would have replaced the blowout preventer with a bigger one and let them keep drilling.

In the North Sea on July 6, 1988, there was a gigantic explosion on an Occidental Petroleum production platform called the Piper Alpha. That tragedy killed 167 people. As a Stanford University report on the incident later said, “It was caused by a massive fire, which was not the result of an unpredictable ‘act of God’ but of an accumulation of errors and questionable decisions.”

The report attributed the blame to the organization, its structure, procedures, and culture. There were flaws in the design, along with insufficient redundancies, and “misguided priorities in the management of the tradeoff between productivity and safety.”

Because of the disaster, laws and regulations were passed in the United Kingdom to increase the oversight, strength, and security of oil platforms.

In the United States, the regulatory agency responsible for well safety was the Minerals Management Service. Why was the MMS ineffective?

The MMS was part of the Department of the Interior. Its job for the last 30 years had been to increase revenue by pushing for more and more oil and gas production. Oil and gas production make up a large percentage of the government’s revenue. That and the IRS are the two big moneymakers that feed everything from our military to Medicare. Even six months of the deepwater drilling moratorium enacted by the Obama administration will have an impact on our deficit in a couple of years. In June, the MMS was renamed the Bureau of Ocean Energy Management, Regulation, and Enforcement.

In the 1990s, you were part of a group from Columbia and the Boeing Company that pushed the oil industry to improve the planning and management of deepwater drilling platforms. What was that effort?

The project, called Northstar, tried to interest the oil companies in systems engineering practices, and particularly the need for systems integration to make deepwater exploration and production more safe, efficient, and effective. This was the “lean management” approach for life-cycle planning and operation of deepwater drilling platforms. Tony Hayward, who was vice president for exploration and production at BP, was a big supporter of our project. However, the additional systems required for lean management were deemed too expensive at the time, and the project was dropped.

Do different companies have different management strategies and operating philosophies?

BP is infamous for pushing the envelope on safety. For example, on March 23, 2005, the company had a dreadful explosion in a Texas oil refinery that killed 15 people and injured more than 170. BP went through lawsuits, they were heavily fined, and the court ordered them to change safety practices and fix basic processes — and it turns out they didn’t. Just last month BP received a record $50.6 million fine from OSHA because they hadn’t corrected some things that they promised the court they would fix five years ago. All this is in addition to the original fines — and to the billions they will be paying for the damage caused by the Gulf disaster.

The BP chief at the time of the 2005 refinery explosion was Lord Browne. He rebranded the company “Beyond Petroleum” — as a green, clean-energy, and safe company. He had a reputation for paying his people bonuses for cost-cutting incentives. But companies have to be very diligent that incentives for cutting costs and increasing profits do not disrupt the culture of safety in any of their operations. Other companies, like Shell and Chevron, have not had the number and magnitude of safety incidents that BP has been troubled with for many years now.

How common are blowouts?

They are more common on land: There were blowouts in Pennsylvania in June and July, for example. But they are rare in expensive offshore reservoirs. They usually happen with smaller oil and gas outfits.

What is the inspection like at these giant wells?

I’ve been on oil rigs in the Gulf of Mexico for months at a time, and the MMS had inspectors there every week. They fly in on helicopters to do surprise inspections of the equipment above the water. The equipment below the water gets inspected between jobs. The BOP of the Deepwater Horizon, which was manufactured by Cameron, would definitely have been scheduled for repair right after the Macondo well was completed because of the hydraulic leaks. I’m sure it

was already booked into Cameron’s overhaul facilities as soon as it came off this well.

The protocols for drilling must include provisions for some kind of worst-case scenario.

That is part of the problem. Humans are not very good at perceiving the worst thing that could happen — until it actually happens. And BP clearly hadn’t considered the possibility of a blowout of this magnitude. I’m sure they dismissed the 3.5-million-barrel Ixtoc blowout of 1979 in the Mexican side of the Gulf of Mexico as being something that could happen to Pemex, Mexico’s state-owned company, but not to BP.

During the spring and summer there were wide swings in the numbers being reported of the volume of oil gushing out of the well. Did BP really not know how much oil was leaking?

Here at Columbia, at the Lamont-Doherty Earth Observatory, they knew, so BP certainly knew. We measure this kind of thing at Columbia all the time in what we call the black smokers on ocean ridges. With lasers, oceanographers can measure the velocity of flow very accurately.

How is that done?

They measure the time in which a particle or a bubble moves over a known distance. In May, Timothy Crone and the people at Lamont came up with an estimate of at least 40,000 to 60,000 barrels per day by analyzing video they had captured right off the television. At the time, BP and the Coast Guard were saying 5000 barrels a day.

How many wells are in the Gulf of Mexico?

Thousands of active wells and tens of thousands of abandoned wells. There has been offshore drilling in the Gulf of Mexico since 1947.

What is the chance of something like the Deepwater Horizon catastrophe happening again in the Gulf, especially as the drilling gets deeper and deeper?

From the old wells, the odds are slim to none: They’re abandoned because they’re already depleted. That said, there are a few people like us at Columbia who have mapped what’s known as recharge: Every so often one of these old and depleted oil wells will come back to life because oil has migrated into a previously depleted reservoir from a deeper source. That’s why they don’t put permanent plugs in them. And of course, BP has also not ruled out returning to produce the Macondo oil reservoir some time in the future.

As far as new wells are concerned, there is production going on as we speak in far deeper waters than the 5000 feet of Macondo. Shell operates a production facility called Perdido in 10,000 feet of water 200 miles off the coast of Texas.

What about the explosion in the Gulf on September 2?

This one was an oil production platform as opposed to a drilling rig like the Deepwater Horizon. It was bringing primarily natural gas to the surface, cleaning and separating water out and injecting it into two gas pipelines carrying the gas underwater to what is called Henry Hub in southern Louisiana for sale most likely to New York and the northeastern U.S. Since the platform had been producing for many years, the gas reservoir was nowhere near as pressurized as with the Deepwater Horizon blowout. In fact, it looks as if a fire actually started in the crew cabins and spread to the gas-collecting facilities, causing the explosion. The operator, Mariner Energy, has also had a checkered safety record in the Gulf of Mexico, including several previous fires on the same platform. It’s another example of the need for tighter oversight of offshore operations in the U.S.

Roger N. Anderson is an energy geophysicist and the Con Edison Senior Scholar at the Center for Computational Learning Systems at the Fu Foundation School of Engineering & Applied Science. At Lamont-Doherty Earth Observatory, he founded research groups that specialized in borehole research, global basin modeling, 4D oil and gas reservoir imaging, and portfolio management. Anderson also teaches Planet Earth in Columbia College’s Core Curriculum.