Christopher Payne Captures the Unexpected Beauty of American Factories

“Most people I know have never set foot in a factory,” says photographer Christopher Payne ’90CC. “Today we have little idea where or how the shirt on our back was made.”

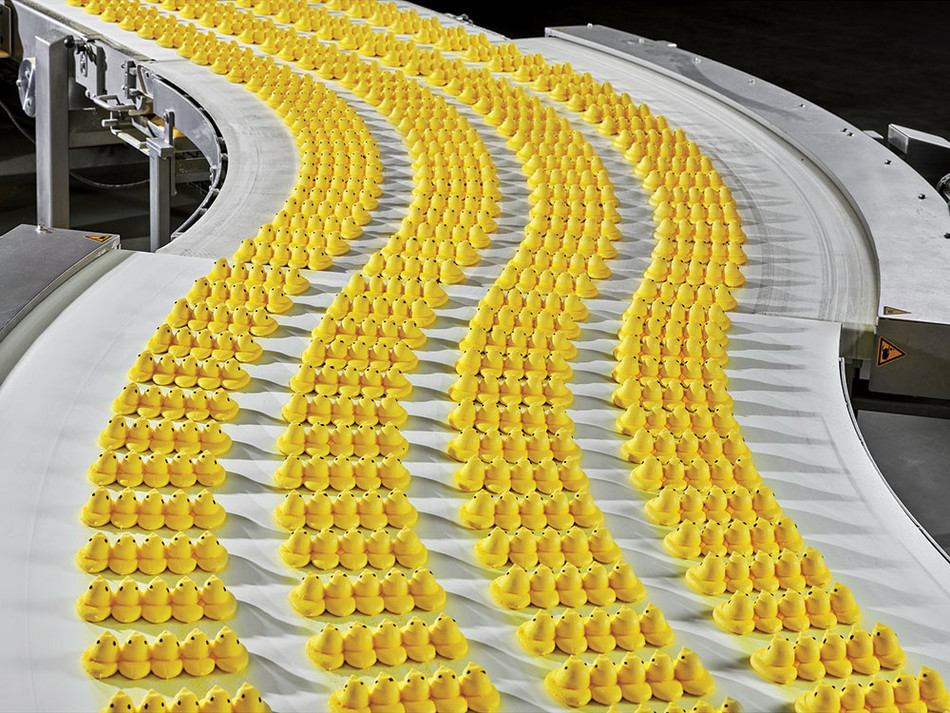

Payne has spent a decade traveling the country, documenting the manufacturing industry, and his new book, Made in America, celebrates both its storied past and what he sees as its hopeful future. In vibrant, intricately detailed images, he captures the making of everything from Peeps marshmallow chicks to forty-ton subway cars. He showcases the traditional craftsmanship and vintage machinery of boat building and textile weaving, while embracing the new technologies needed to make high-voltage undersea power cables and commercial aircraft.

Payne, who studied architecture at Columbia, says a class with history professor James P. Shenton ’49CC, ’54GSAS “lit a fire” in him to explore the industrial remnants of New York City, and after graduating, he began photographing the city’s electric substations, then the Steinway piano factory. He worked as an architect for twelve years, but he realized that he preferred chronicling existing spaces to designing new ones, and he turned to photography full-time.

The images in Payne’s book, many of which were originally commissioned by the New York Times, are visually arresting, but they also tell a bigger story about our cultural and economic climate. With environmental crises and political instability threatening the global supply chain, American manufacturing is making a comeback, and Payne is excited about the shift. “There is, for sure, a certain romance in the idea of making our own goods here in the US,” he says. “But it is no longer entirely nostalgia: it is also opportunity and necessity.”

This article appears in the Fall 2023 print edition of Columbia Magazine with the title "Factory Frames."