3D printers are already being used to manufacture a range of products, from prosthetics to pistols, and someday there might be one on every kitchen counter, ready to download and print dinner.

While several entrepreneurs are applying the principles of digital manufacturing to cooking, researchers in Columbia’s Creative Machines Lab are at the forefront of this culinary revolution. The 3D-food project — led by engineering professor and roboticist Hod Lipson —began more than a decade ago when students tried putting chocolate, rather than plastic, into 3D printers. The results were so intriguing that Lipson made digital cooking a primary focus of the lab. His team has even collaborated with professional chefs from New York City’s International Culinary Center in an attempt to create more palatable printouts.

Recently, the Columbia team has been developing a 3D printer that can cook while it prints. “We’re making a machine that’s built specifically for food, rather than modifying an existing device,” says Evan Murray Hertafeld, a fourth-year electrical-engineering undergraduate who is the team’s student lead.

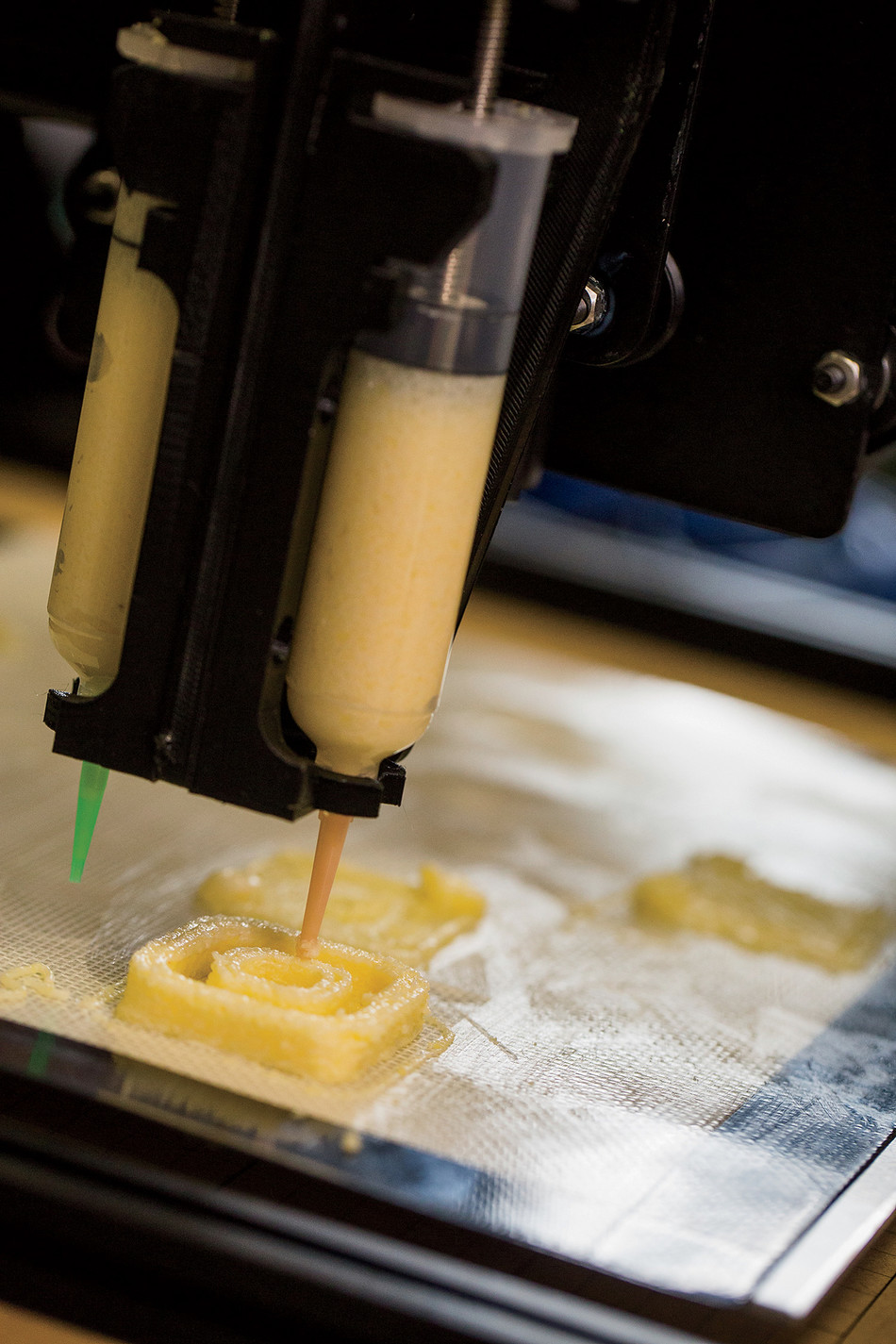

The Columbia prototype is unique in its ability to cook multiple ingredients at varying temperatures and rates. These ingredients, usually in the form of soft pastes or purées, are extruded from the machine, layer by layer, onto a surface that can be heated like a traditional stovetop. A software program determines the cook time and directs an infrared “spotlight” at sections that require additional heat.

As for consumer appeal, the goal is not to replace conventional cooking; rather, printing food opens up possibilities for culinary innovation, especially in the area of nutrition.

“We’ll have the ability to optimize food according to a person’s dietary needs,” says Lipson. “Your breakfast wouldn’t be made out of standard foods. It would consist of whatever is good for you on that day, based on your biometrics.”

Hors d'Oeuvres with Dimension

1. The printer's robotic arm can hold several food cartridges. This appetizer will be made out of goat-cheese polenta and beet purée.

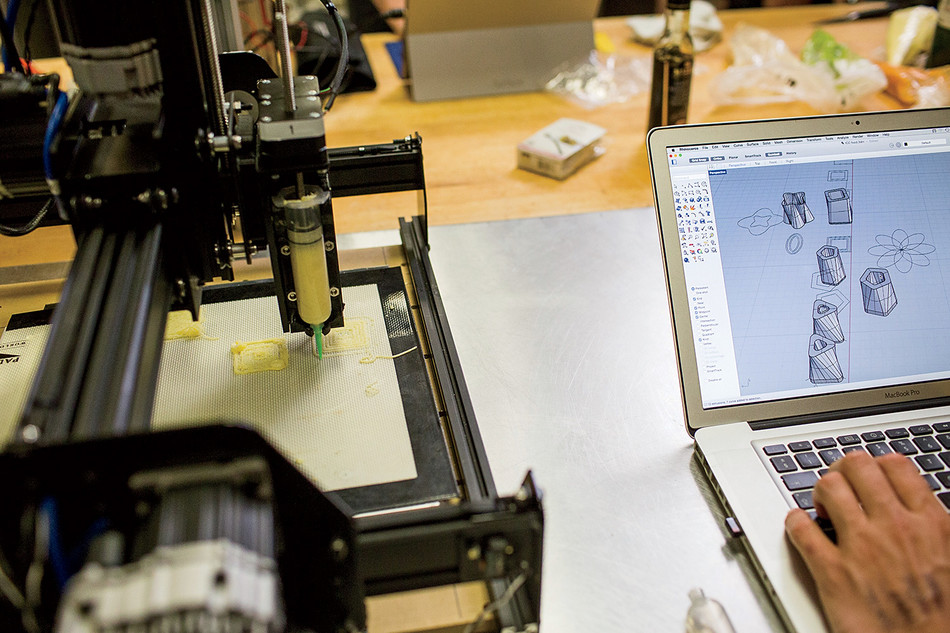

2. Students program software that directs the printer’s movements.

3. Multiple layers are extruded to create edible structures the newest printer prototype can also cook the ingredients.

4. The bite-size printed appetizer is garnished and ready to eat.

Photos by Timothy Lee Photographers