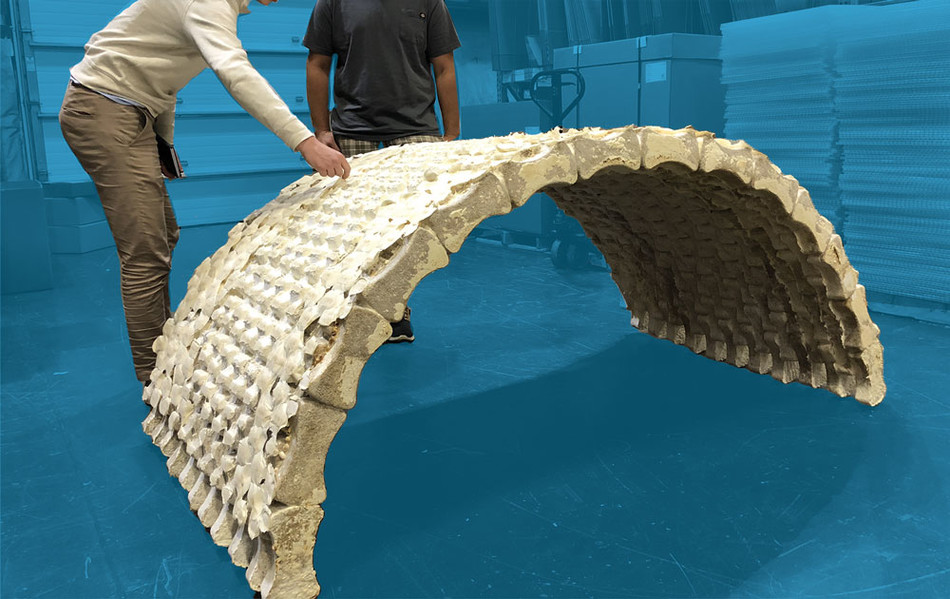

In an effort to move away from the devastating environmental impacts of the cement and concrete industries, scientists have been coaxing microorganisms such as fungi and bacteria to grow into rock-solid substances that can serve as sustainable building materials. Such biomaterials, which require little energy to produce, are often fireproof, waterproof, and completely biodegradable.

Now a team of researchers led by Columbia synthetic biologist Harris Wang has created fungus-based bio-bricks with an added benefit: the bricks remain alive long after their manufacture, enabling them to bond to each other without mortar and even heal themselves, should cracks appear.

“If a living brick gets damaged, all you have to do is pack some additional fungus into the crack and it will mend itself in a few days,” says Ross McBee ’22GSAS, who helped lead the project while a graduate student in Wang’s laboratory. The team’s research appears in a recent issue of the journal Nature Materials.

The bio-bricks are made of Ganoderma fungus, a type of mushroom commonly found on tree trunks. Columbia scientists say that they could be especially useful in remote settings where construction materials aren’t readily available and where there is an urgent need to erect temporary structures, such as at the scenes of natural disasters. They say that nearly limitless quantities of bricks could be produced with just a few sacks of preserved mushroom roots, also known as mycelium.

“All you’d need to find onsite is some starchy plant byproducts to feed the fungus, like straw or corn stalks or hemp,” says McBee. “And since the material you make is alive, you can keep generating more and more of it simply by adding more feedstock. Then, after you’re done with the bricks, they’ll disappear back into nature.”