The first night on the boat everyone got sick. Agustina Besada ’15SPS, her husband, and two friends had left the Mill Basin boatyard on Brooklyn’s southeast shore heading toward Bermuda, and now, somewhere in the chop off New Jersey, Besada was having second thoughts.

For the past year, the thirty-five-year-old entrepreneur had been getting ready to launch Unplastify, a business startup aimed at helping schools, companies, and governments assess their relationship to plastic and reduce their dependence on it. To emphasize the toll of single-use plastics — bags, straws, cups, packaging, utensils — on the environment, Besada decided to embark on a sailing trip. She would cross the Atlantic to Europe — sail past the Azores and through the Strait of Gibraltar, collecting water samples along the way. In Europe she would meet with sustainability experts and then voyage, using the trade winds, to Brazil. There were easier ways to make a statement, but the problem called for a sweeping gesture.

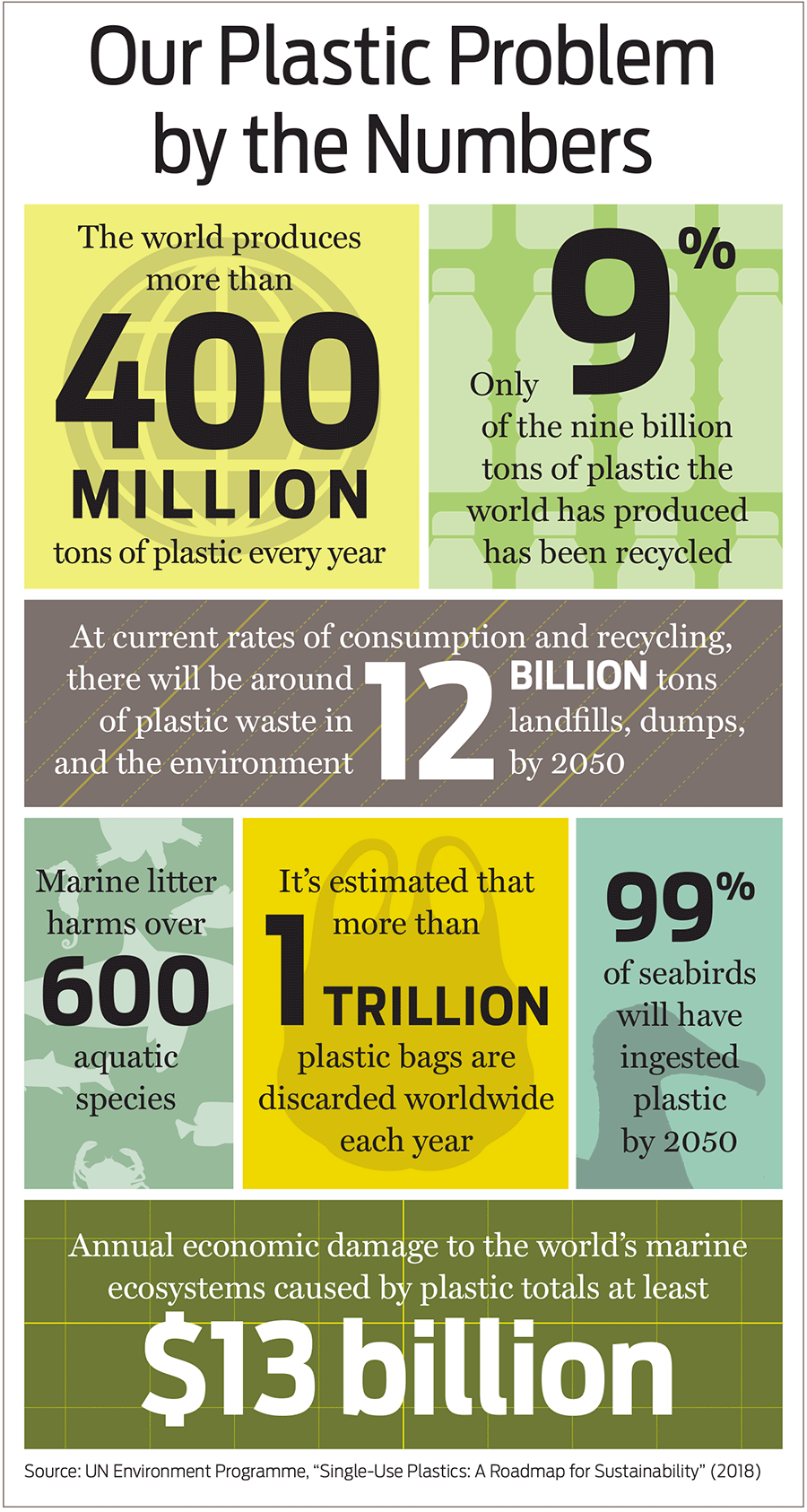

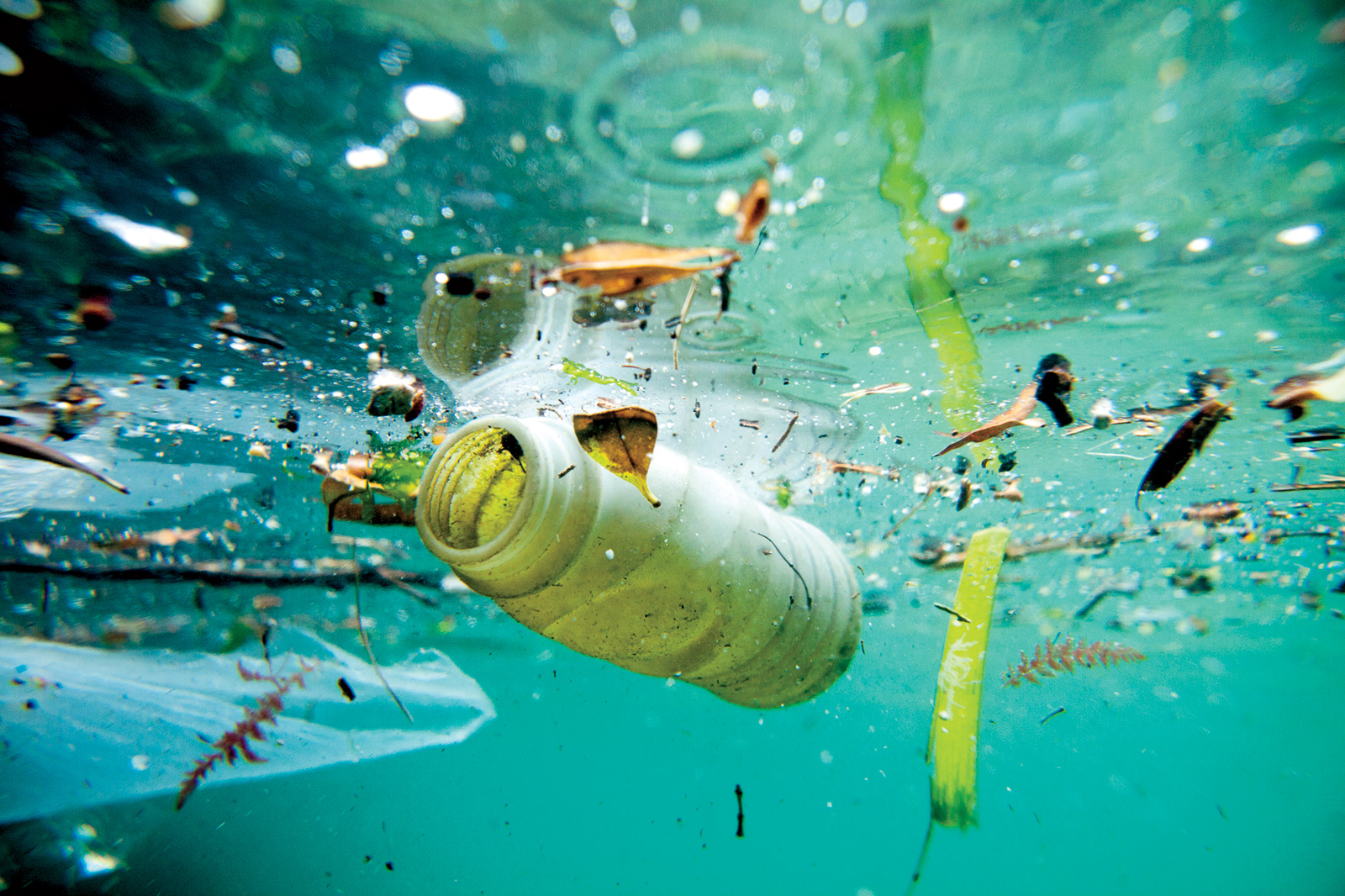

The world produces four hundred million tons of plastic annually, nearly half of which is considered single-use. Each year, more than eight million tons of plastic waste ends up in the ocean. That’s a rate of almost fifteen tons every minute. Some of this non-biodegradable flotsam washes up on beaches. It fouls habitats and mars scenery. It becomes accidental food for seabirds and sea turtles. In the water, it agglomerates into giant fields of debris, the largest of which, swirling between California and Hawaii, is twice the size of Texas.

“Plastic is an amazing material,” Besada says. “My boat is made of plastic. We need plastic. But there are so many products we use for a few seconds or minutes or hours — a coffee pod, a shopping bag — and then it lasts for five hundred years.”

Besada, who grew up in Argentina, became fascinated with waste management in high school, when she volunteered in rural recycling programs, but the scope of the plastics glut didn’t really hit her until many years later. It happened at a recycling center in Brooklyn. She had joined the center’s board while getting her master’s in sustainability management at Columbia’s Earth Institute through the School of Professional Studies, and one day in 2017, standing amid “mountains of plastic” — mostly bottles — she was struck afresh with amazement and horror. The situation, she would later say, seemed “completely out of control.” She knew that 91 percent of plastics never got recycled and that plastic production was only increasing.

Besada knew she had to act. It was time to unplastify. She and her husband, Ignacio Zapiola ’11LAW, love sailing, so Besada, who’d never been on a boat for more than twenty-four hours, hatched the idea of a transatlantic expedition. She and Zapiola bought a twenty-year-old, thirty-seven-foot sailboat in Connecticut and named it Fanky, after a song by the Argentinian musician Charly García. Besada figured if she was going to advocate for oceans, she would have to go into the belly of the beast.

The planning took months. Besada learned how to fix a diesel engine and do electrical work. She obsessed over crucial purchases: which life raft, which emergency beacon? Every detail mattered. Finally, in March 2018, Besada and Zapiola sold their belongings and moved out of their Brooklyn apartment and onto the boat in Mill Basin. That May, at the start of a weather window that would get them to South America before hurricane season, they welcomed aboard two friends with more extensive sailing experience, and the four of them set out. Now, in the pitch and heave off New Jersey, with everyone seasick and ten thousand nautical miles ahead of them, Besada kept reminding herself what was at stake.

Earlier this year, a beached whale in the Philippines was found to have eighty-eight pounds of plastic, mostly bags and nets, in its digestive system. A few weeks later, a pregnant sperm whale washed ashore in Italy, its stomach filled with forty-eight pounds of plastic. The list of casualties goes on. Millions of animals die with bags and nets and buckets in their guts, but symbols emerge: the dead albatrosses on Midway Atoll, their insides stuffed with colorful, undigested bites of plastic; an endangered sea turtle in Costa Rica with a plastic straw lodged in its nostril and throat; a Missouri turtle whose shell grew around the plastic six-pack ring that had ensnared it as a hatchling.

But the trouble goes beyond the plastic we can see. Plastic doesn’t break down but rather breaks up into smaller and smaller particles. Granules less than five millimeters across — the length of a pencil tip — are known as microplastics. Many of the microplastics in the oceans are invisible to the naked eye, the hidden ingredients of a slow-cooking plastic broth.

“Smaller plastics are our biggest problem,” says Joaquim Goes, a marine biologist at Columbia’s Lamont-Doherty Earth Observatory (LDEO). Goes, along with geochemist Beizhan Yan, students in LDEO’s high-school intern program, and high-school science teacher Debra Magadini, has been studying microplastics in the waterways of New York City and in the digestive tracts of local marine life. Usually these particles are fragments from larger objects, but some, like microfibers and microbeads, are made to be small. Microbeads, often used as abrasives, are added to cleansers, detergents, paint strippers, and cosmetics, and are so tiny that they escape from wastewater-treatment centers. In 2015, President Barack Obama ’83CC signed the Microbead-Free Waters Act, making the US the first country to ban microbeads, though loopholes and lack of disclosure have made the law difficult to enforce.

“Microplastics are in the guts of every animal we’ve studied,” Goes says.

In their surveys of eight waterways around New York, including the Hudson, Harlem, and East Rivers, the LDEO team has found high concentrations of microplastics — mostly acrylic polymers, used in paints, clothes, and medical devices. Under ultraviolet light, microplastics will glow, making them easy to spot in the guts of marine organisms like phytoplankton, which are consumed by mussels and oysters. The team has also looked at the plastic-flecked innards of speck-sized crustaceans and the small fish that eat them — in particular, mummichogs and banded killifish from Piermont Marsh, twelve miles upriver from Manhattan. Casting a wider net, the researchers detected microplastics in canned clams from China and farmed shrimp from South America. (Goes notes that on many shrimp farms, microbeads are added to feed pellets to keep them afloat.)

Another major concern is that microplastics tend to attract compounds from substances like pesticides and pharmaceuticals. “Those chemicals don’t like water,” says Yan. “They do like plastic. So they naturally attach to it.” When these grains of plastic collect on the surface of the water, they come into contact with bacteria and algae, which can absorb them. Those organisms, which are eaten by other marine animals, become “vectors of chemicals,” says Yan.

Goes is now focusing on a dominant source of microplastics: clothing. Many synthetic materials and cotton-synthetic blends shed fibers when they are laundered. “Fleece jackets and flannel shirts are big culprits,” Goes says. “These fibers — thinner than the width of a hair — aren’t trapped by waste-treatment plants. And so they, too, end up in the waterways and in the guts of whatever animals are in the water, especially bivalves and zooplankton.”

Last year, Goes went to a fashion conference and spoke about the problem. Afterward, designers and retailers approached him with offers to help. Goes asked them to send fabric samples, which he keeps in bags on his desk: blends of cotton, polystyrene, and nylon. “We want to get an index on shedding — find out which fibers are involved and inform the companies,” says Goes, who in the absence of funding has assigned the survey to the high-school interns. “If companies know which fibers are shedding most, they can improve the manufacturing of those fabrics.”

Though the plastic fibers are minuscule — check out the fuzz on your gym clothes — they add up quickly, traveling by the trillions from washing machines to the sewers and eventually into the sea. “There is a bioaccumulation factor,” says Magadini. “We’ve done preliminary studies looking at the uptick of marker plastics in these smaller organisms, which end up inside larger organisms that are prey for striped bass and lots of other game fish. What we’re really talking about here is the base of the food chain.”

In 1907, in a lab in Yonkers, a Belgian chemist named Leo Baekeland, who would later become a professor of chemical engineering at Columbia, mixed phenol (carbolic acid) with formaldehyde. The result was Bakelite, the first synthetic polymer, or plastic. Polymers are large, dense molecules made up of repeating chains of smaller identical subunits called monomers. There are useful polymers in nature, like cellulose (plant fiber), silk, and wool, but Bakelite could be shaped and hardened into all sorts of things: telephones, jewelry, radios, lamps, poker chips.

“Early plastics transformed consumer culture,” says Susan Freinkel ’84JRN, author of Plastic: A Toxic Love Story. “Imitation luxury objects were suddenly widely available.” In her book, Freinkel tells the story of the “humble comb,” which went from expensive tortoiseshell or ivory to cheap plastic overnight. “You no longer had to be wealthy to have a pretty comb in your hair,” Freinkel says. “A trip to Woolworth’s would do.”

This change heralded the plastic revolution of the coming decades, which saw such miracles of versatility and durability as plastic wrap, vinyl, nylon (introduced by DuPont at the 1939 New York World’s Fair), polyester, and polypropylene (used in textiles and food containers). In the 1930s, chemists began experimenting with ethylene, a hydrocarbon made from petroleum or natural gas. They found that the ethylene molecule could, with chemical stimulus, be polymerized. The result, polyethylene, fueled an explosion of consumer plastics. In the 1940s and ’50s, three giant polymer-based products appeared: Saran Wrap (polyvinylidene chloride), Tupperware (low-density polyethylene), and Lycra (polyurethane).

“Plastic is everywhere,” says Freinkel. “Most food packaging is made from plastic. It allows food to travel around the globe and affords conveniences like bagged salad or squeezable mayonnaise. Plastics enable modern medicine and electronics. Cars are made with a high percentage of plastic. My glasses, my computer — it’s endless. Plastics are integral to every facet of our lives today, for better and worse.”

Moreover, asserts Freinkel, the fracking boom has weakened markets for alternative plastics in the US. “You can make plastics out of plenty of materials — corn, sugar cane, agricultural waste — but fracking has made it ever cheaper for petrochemical companies to produce plastic from natural gas.” (A molecule-altering process called “cracking” turns the gas ethane into ethylene.) “New facilities are being built in the US to bump up production of synthetic plastics, even as awareness of the problem spreads. Polyethylene is so cheap to produce that there’s no incentive for big companies to find more sustainable methods.”

Once Fanky crossed the Gulf Stream, the passage became much smoother, and Besada, feeling better, began to gather water samples. A non-scientist with a bachelor’s degree in industrial design as well as a certificate, earned in 2017, from Columbia Business School’s Entrepreneurship and Competitiveness in Latin America (ECLA) program, Besada had wanted to make whatever measurements she could during the voyage. She had brought along a filtering device called a manta trawl that could be towed behind the sailboat. The trawl, with its wide mouth and flat wings, gulps surface water, which is then sieved through a tapered net. Within hours, the net collected hundreds of tiny pieces of plastic.

The crew stopped for a day in Bermuda to fix a broken autopilot, then resumed the journey. Three days later, in the middle of the Atlantic, the steel-blue sea, furrowed and lacquered, rolled out to a serene flatness, “like a mirror,” as Besada wrote in her log. It was exceedingly pleasant.

Besada, standing on the deck, then noticed something floating. It was not, as a sea turtle might suppose, a tasty jellyfish. It was a plastic bag. Besada saw another object — a beach ball. Nearby she saw pieces of netting. She saw water bottles and plastic containers and things that had broken off from larger objects, parts she did not recognize, bobbing and lolling in the sun.

“Overall, plastics are among the most useful materials invented by humankind,” says Nickolas Themelis, founder of Columbia’s Earth Engineering Center and a leading expert on waste management. “But they’ve gotten a bad name, because we have not yet found a way for them to be used well at the end of their life.”

Municipal recycling handles consumer plastics that can be melted down and made into other objects (water bottles often become carpet fibers or grocery bags). In the US, where less than 10 percent of plastic is recycled (compared to 30 percent in Europe), tight budgets, inefficiencies, and China’s 2017 decision to stop buying used paper and plastic from the US (officials said the recyclables were too mixed up with garbage to make recovering them worthwhile), have wiped out recycling programs across the country.

“Recycling has reached its limit,” says Themelis. “If you assess the environmental impacts of recycling a plastic container, for instance — the collection, processing, and eventual end of life — it doesn’t pay off ecologically. But we do it because it seems sensible and it makes us feel good.”

Part of the reason recycling plastic is so complicated, he explains, is that plastic comes in many thousands of different types (change one molecule in a polymer and it becomes potentially patentable), and many plastics, such as those used for aircraft parts, insulation, and waterproofing, have chemical bonds that prevent them from being melted and reshaped. “Unlike metals, most plastics cannot easily return to their original, basic forms,” Themelis says. “When there is a limit to recycling, what can we do?”

Themelis, who coauthored a 2014 report for the American Chemistry Council on the energy and economic value of non-recycled plastics, believes we already possess effective alternatives to overflowing landfills and plastic-choked oceans. One is a plastics-to-fuel process called pyrolysis, in which plastic is subjected to high heat in the absence of oxygen and converted into oil, which can be used to run energy plants and vehicles. “In India and China, existing pyrolysis plants can handle up to ten tons of plastic a day — a small amount. For plastics pyrolysis to be economically viable in the US, where labor is more expensive, a plant’s capacity would have to be much larger.”

Another, more feasible solution is waste-to-energy plants. Cheaper than pyrolysis, which requires the separation of plastics from the waste stream, waste-to-energy uses combustion to turn mixed waste, composed mainly of paper, food, yard trimmings, and plastics, into energy. “Instead of using coal, gas, or oil to generate electricity and heat, you use mixed waste,” Themelis says.

Many environmental groups oppose the burning of waste, not just for the unavoidable emissions of carbon dioxide and other gases but because reliance on the method could promote the continued production of cheap plastic.

Themelis figures the math differently. “If you put one ton of municipal solid waste through a waste-to-energy plant instead of in a landfill, you save up to one ton of carbon dioxide,” he says. “In the landfill you have methane emissions” — one of the most potent greenhouse gases, released by rotting organic matter, like food and yard waste — “and you use up land. So there’s no question that waste-to-energy plants are cleaner and more efficient.”

He sees waste-to-energy as a complement to recycling and reduction, not a replacement, and he applauds China for raising its capacity from fifty waste-to-energy plants to some three hundred in the past decade. There are about seventy such plants in the US, mostly in what Themelis calls the “more advanced” Northeast. He wants to see more. He points to the EU and Japan, where landfills are giving way to waste-to-energy and recycling.

“So now we have a practical way to turn unrecyclable plastic into energy, but we still have outdated notions about burning our waste,” Themelis says. “A hundred years ago people started using furnaces to burn waste. In New York City there were furnaces in thousands of apartment buildings. There was a chute, and you’d throw the stuff down. That, of course, was no good: you could not afford to have environmental controls with twenty thousand furnaces. But pressures from environmental groups and citizens led to cleaner, gas-controlled systems. That’s what these plants have. It’s like trains: they ran on coal, there was terrible pollution, but that doesn’t mean the trains of today are the same.”

Pyrolysis and waste-to-energy may be viable options in some places, but according to Ranjith Annepu ’11SEAS, there is no one-size-fits-all answer. A former student of Themelis’s, Annepu directs global waste operations for Kimberly-Clark, makers of Kleenex tissues, Scott paper towels, and Huggies disposable diapers.

“Asking what’s the best way to address plastic waste is like asking a chef what’s the best way to cook,” Annepu says. “The chef’s response would be, ‘That depends on what you want to cook, the available ingredients, and the tools you have access to.’ In other words, to understand the issue you must consider the enormous diversity in our world. There’s no single plan, no one type of mindset or culture. The solutions depend on the resources available, the infrastructure, the waste stream, and the local governance.”

While at Columbia, Annepu worked with the nonprofit advocacy group Ocean Conservancy, analyzing different technologies to keep plastics from ending up in the oceans. His oft-cited master’s thesis was on sustainable solid-waste management in India.

In his job, he is responsible for diverting waste from eighty-five mills on six continents. “You can imagine the variety in all these different places, from landfilling to recycling,” Annepu says. “The goal is to divert 100 percent of our waste from landfills to a mix of recycling, composting, and anaerobic digestion. We’re at 96 percent. It’s a diverse world, and we need diverse solutions.”

When it comes to remedying the polymer predicament, Kartik Chandran, a professor of earth and environmental engineering at Columbia, has got one word for us: bioplastics.

Chandran, a 2015 MacArthur Fellow known for using living bacteria to convert food waste, sewage sludge, and fecal sludge into fuel and fertilizer, is applying the same principles to make biodegradable polymers out of organic waste.

In a laboratory in the Mudd Building, two kitchen-blender-sized cylinders hold the promise of a new generation of plastics. These are reactors, or fermenters, which provide specific conditions for specialized microbes to thrive on a particular medium — in this case, food scraps from John Jay Hall.

“We have to run these reactors under very specific conditions that allow these organisms to proliferate,” Chandran says. The bacteria in the first reactor are capable of secreting enzymes that break down, or depolymerize, the rotting food’s proteins, fats, and starches into smaller molecules and release them outside their cells. “We are going from high molecular weight to very simple organic carbon monomers,” says Chandran.

The team then harvests the carbon monomers and places them in the second reactor, which is populated with totally different organisms. These microbes consume the monomers and turn them into usable polymers, which can then be made into things like bags, utensils, and straws. Though far outgunned by the trillion-dollar synthetic-plastic market, the $20 billion bioplastics industry is expected to grow rapidly in coming years as increasing awareness swells demand.

For Chandran, the goal is efficiency: he wants to engineer the microbes to be versatile, able to depolymerize the material whether it’s cafeteria leftovers or municipal sludge. “The engineering process should be agnostic to the feedstock,” Chandran says. “We want to produce the most attractive biopolymer on earth.”

Sailing from Bermuda to the Azores took two weeks. One night, out in the devouring darkness, while Besada was sleeping — “you sleep with one eye open” — she heard something. Everyone heard it. There were always noises, and you came to recognize them: flapping sails, glugging waves. But this time there was an impact, “like hitting the ground in the middle of the ocean.” There was a half-moon out, and someone on deck spied the cause of the collision. It was awake now and retreating: a whale. It had been sleeping on the ocean’s surface.

The crew began inspecting the boat. No water was coming in, and Fanky, none the worse for wear, reached Europe. For the next six weeks, Besada traveled by air, from Spain to Norway, talking to sustainability experts, regulators, and educators. In London she met with the NGOs behind the #OneLess campaign (motto: “Because everything we do touches the ocean”), a local movement to reduce plastic bottles and other single-use plastic in that city.

Besada wasn’t looking for one answer. But the big takeaway from her fact-finding mission was the consistent response she received to her key question: How do we change our relationship to plastic? Almost everyone gave the same reply.

“They all said education,” Besada says. “It was so clear. I was looking for sophisticated solutions, but even scientists said ‘education’ — teaching people about the severity of our plastic problem. This is the starting point to change behavior.”

As soon as Besada returned, on stormy seas, to South America, she began developing educational programs and talking to school administrators. She is now working with high schools in Uruguay, Chile, and Argentina. “We go to the school, give a talk, and moderate a workshop in which students design strategies to reduce plastic in their schools,” Besada says. “Some teams are working on implementing new regulations, others on awareness campaigns, and others on finding ways to reduce plastic use in the cafeteria. The response of teenagers has been amazing.”

Though it’s a pilot project, Besada designed the curriculum so that it could be applied to a hundred schools in different countries. “If it works,” she says, “we’ll scale it: it must be done on a large scale. This isn’t just about recycling at home. This is about asking kids questions: How would you change your school? How would you have an impact?

“Once we see people becoming more aware, we can provide solutions: rethinking how we use plastic in our day-to-day lives and developing products that can replace disposable plastics. It’s not about simply providing information. This generation has much more access to information than any before it. The challenge is to get them excited and inspire them to take action.”

“It’s time we made some changes here at home,” says Joaquim Goes at LDEO. “Columbia is full of plastic: forks and knives and containers. Even in places like Mumbai, which I just visited, they’ve switched over to other materials: forks and knives made of wood, plates made of cornhusks, paper straws. The high-school interns in our lab tell us that their school cafeterias go through thirty or forty boxes of plastic forks and spoons every day. Switching to wooden spoons and forks and paper straws in schools would make a huge difference. I’d like to see high schools and colleges ban this sort of plastic. Alternatives exist. In fact, the use of cornhusks could give rise to a huge industry in the Corn Belt of the Midwest, because the plates are beautiful.”

That all sounds good to Agustina Besada. She can get behind a common-sense ban.

“A strong ban sends a message,” she says. This spring, New York became the second state, after California, to pass a ban on most single-use plastic bags. (The law goes into effect next year.)

With the ocean voyage over, the next phases of Unplastify — education and action — are picking up steam. In addition to working with schools, Unplastify was hired this spring to advise a large South American restaurant chain seeking to unplastify its operations.

Meanwhile, at a marina in Montevideo, Uruguay, 125 miles east of Buenos Aires across the Río de la Plata, a sailboat rocks gently in its berth. Besada and Zapiola, who divide their time between Argentina and New York, get over to Uruguay once in a while to take Fanky out. They want to sell the boat, but they’re still attached to it.

“The boat was our home for so long — our amazing house on the ocean,” Besada says. “But the work to be done now is on land.”