If you’ve ever tried gift-wrapping an oddly shaped present, you can appreciate the challenge that surgeons face when grafting artificial skin onto the human body. Like wrapping paper, engineered skin comes in flat pieces, which can be difficult and time-consuming to stitch together around someone’s hand, foot, knee, or face.

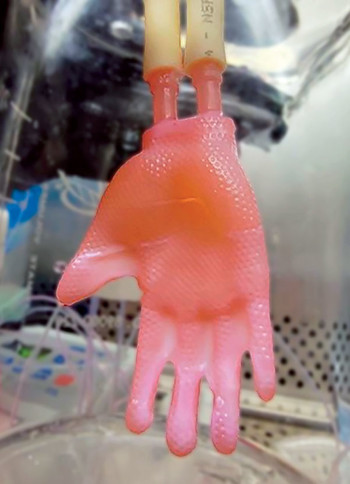

Columbia bioengineers led by Hasan Erbil Abaci appear to have solved this problem by devising a way to grow skin in complex shapes. First they create a laser scan of the injured body part. Then they use a 3D printer to create a plastic scaffold in the same shape and seed it with skin cells and nutrients. Three weeks later, a perfectly proportioned skin graft is ready for transplant — to be slipped onto, say, a severely burned hand like a glove.

The Columbia researchers, who have shown that their technique works in mice and hope to begin human trials in a few years, say the method could dramatically reduce the length of time required for surgeries, minimize the need for suturing, and make the end result stronger and more natural-looking.